The 5S management technique

The 5S methodology is a proven system for maintaining a tidy, organized, and safe work environment. By implementing its five simple steps, businesses can improve workplace efficiency, reduce the risk of accidents, and promote employee well-being. Originally developed in Japan, 5S is adaptable across various industries—including factories, workshops, offices, and even home environments.

We provide a range of 5S solutions to support workplace optimization, including:

✅ Labels & Signage – Clearly mark storage areas, equipment, and workflows for better organization.

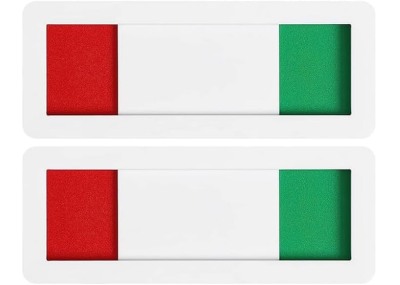

✅ Red/Green Indicators – Visual management tools for process status, inventory levels, and safety alerts.

✅ 5S Cleaning Boards – Keep essential cleaning tools visible and accessible to maintain a tidy workspace.

✅ Shadow Boards – Ensure tools are always in the right place with custom layouts for efficiency.

✅ Floor Marking Tape – Define work zones, aisles, and hazard areas with durable, high-visibility markings.

At CleanLabs, we’re committed to continuous improvement by offering practical, high-quality solutions tailored to Industry 4.0 principles. Contact us today to optimize your workspace with innovative 5S tools.

Order Codes

- CLS-1477SH - Sample holder/carrier

- CLS-1445TG - RED/GREEN 5S tags

- For shadow boards please contact us.

- For labels and signage please contact us.